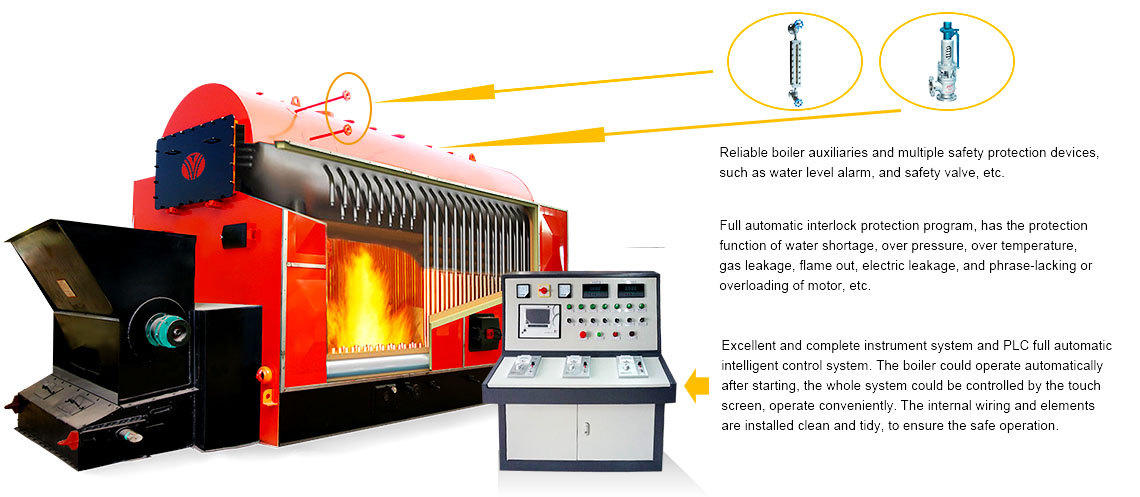

Rice Husk fired chain grate steam boiler is single drum water tube and fire tube boiler, combustion equipment is chain grate. Water wall tubes at left and right sides of furnace are the radiated heating area. the two wings at furnace and screw fire tube in the drum are convection heating area. The rice husk fired steam boiler uses the upper drum, water wall tube and head are in symmetrical arrangement mode. The drum is welded assembly by cylinder and front back tube plate. This furnace structure in reasonable arrangement and high efficiency. This rice husk fired chain grate steam boiler uses the new scientific achievement, such as arch tube plate, screw fire tube to solve the problem of tube plate flaw, water wall tube explosion, low efficiency, insufficient output, poor adaptability of different biomass fuel, improve the heat transfer.

| Model | Steam capacity(t/h) |

Rated pressure (MPa) |

Thermal efficiency (%) | Available fuel | Fuel consumption (kg/h) | Overall Dimension L×W×H (m) | Weight (ton) |

| DZL1-0.7/1.0/1.25-T | 1 | 0.7/1.0/1.25 | 82 | Biomass pellet | ~200 | 5.1×2.2×3 | 17 |

| DZL2-0.7/1.0/1.25-T | 2 | 0.7/1.0/1.25 | 82 | ~400 | 5.5×2.3×3.3 | 23 | |

| DZL4-1.25/1.6-T | 4 | 1.25/1.6 | 82 | ~800 | 6.6×2.6×3.6 | 25 | |

| DZL6-1.25/1.6-T | 6 | 1.25/1.6 | 82 | ~1200 | 8.2×2.9×3.8 | 35 | |

| DZL8-1.25/1.6-T | 8 | 1.25/1.6 | 82 | ~1600 | 8.1×3.1×3.8 | 45 | |

| DZL10-1.25/1.6-T | 10 | 1.25/1.6 | 82 | ~2010 | Up 7.7×3.2×3.6 Down 8.6×3×2.6 | Up 23 Down 28 | |

| Note: 1. Parameter is for reference only, if any changes should follow the factory technical data. 2. Our company can design boiler products based on customers’ requirement and different biomass fuels. |

|||||||

Contact us now if you have any question about our company and products [email protected]. Any of your inquiry and suggestion will be highly appreciated. We will keep your information completely private.

WANT TO FIND A BOILER FOR YOUR COMPANY ?CONTACT US