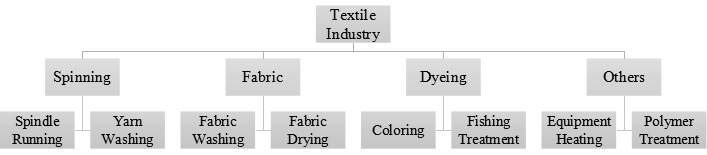

The utilities that provide services to textile industry processes includes electricity, steam, water, and compressed air. Steam plays an significant role in textile industry, it is the vaporized state of water that contains heat energy and transfer the energy into a variety of processes. Boilers are the common equipment to produce steam, which are also called steam generator.

Uses of boiler & steam in textile industry

Types and specifications of Boilers Suitable for Textile Industry

WNS Horizontal Type Oil Gas Fire Tube Steam Boiler

WNS Horizontal Type Oil Gas Fire Tube Steam Boiler

Capacity: 1~30 t/h

Fuel: heavy oil, diesel, natural gas, LPG, city gas, coke gas, etc.

WNS series steam boiler smoke gas three pass and wet back structure, achieve high thermal efficiency (98%) . This is fire tube boiler, low water quality requirement, the failure rate is lower than 0.1. Adopts international excellent burner, PLC automatic control cabinet, and safety interlock device, operate safely and conveniently.

Oil Gas Fired Once Through Structure Steam Boiler

Capacity: 0.1~2 t/h

Fuel: heavy oil, diesel, natural gas, LPG, city gas, coke gas, etc.

.jpg) SZL Biomass Fuel Water Tube Steam Boiler

SZL Biomass Fuel Water Tube Steam Boiler

Capacity: 0.5~25t/h

Fuel: wood, bagasse, straw, rice husk, and other biomass fuels.

Biomass fuel is low polluted, reproducible, and low cost. SZL double drum boiler adopts membrane wall and automatic feeding system, has the advantages of high thermal efficiency (97%), sufficient output, high steam quality, and low operating cost.

Price of Textile Boilers

The price of textile boilers are based on the capacity and accessories. Generally, the accessories of textile boilers include burner/grate, electric controller, steam header, water softener, BFW pump, platform ladder, and chimney, etc. If you would like to use the specific devices (brand, materials, quantity, etc.) or the additional equipment (air preheater, economizer, condenser, etc.), the prices are quite different. So, if you would like to get the exact price, please inquire for the details.

How to Select a Proper Boiler for Textile Industry

1. Determine the capacity of the boiler. The boiler capacity should based on the Heating Load Curve or Heat Balance Diagram, and includes the heat loss in pipelines, self-used heat of boiler room, available used waste heat. While, usually, it is difficult to get the Heating Load Curve, the heating load could get based on the max thermal consumption per hour within production/heating/domestic, and then determine by using the coefficient.

2. Determine the heating supply medium. Generally, the textile industry use the steam boiler for production. If there are large hot water demanded as well, both steam boiler and hot water boiler should be used.

3. Determine the boiler heating parameters, including pressure, temperature, etc.

4. Determine the boiler efficiency. In order to benefit for economic management, the boilers should have high thermal efficiency, and the boiler output, quantity and other performances have to adapt to the change of heat loading.

5. It’s better to select the boilers with same capacity or combustion equipment. If different, the max limitation is two models, to decrease the problems of equipment layout and management.

.jpg)