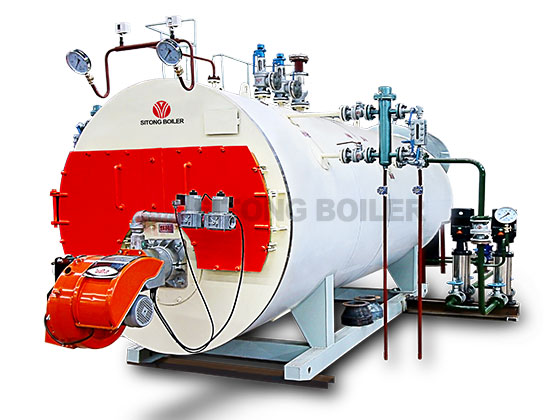

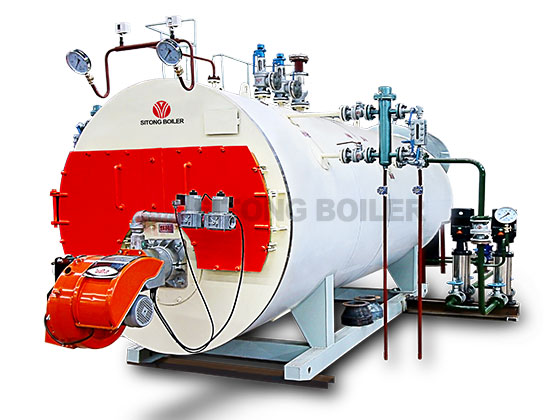

Sitong WNS series gas oil steam boiler is horizontal three-return fired tube steam boiler with wet back structure. The high temperature flue gas injected into the atmosphere after convection heat transfer through the reversal chamber into the first flue tube bundle, and then from the front smoke box with turning 180℃ into the second flue tube bundle. The structure of Sitong WNS Series steam boiler is compact and reasonable. This boiler is composed of three parts: boiler body, chimneys and piping systems. Boiler body and chimney are manufactured in our factory, and piping systems are installed when the boiler arrives at the destination, the technical team could help to install the boiler or offer the technical support if necessary. Moreover, the quality of the boiler can be guaranteed.

1. Sitong patented technology

100% completely butt welding, minimum stress, and the quality is more reliable.

2. Large diameter corrugated furnace

Combustion chamber is composed by large diameter full corrugation furnace, large combustion space, sufficient combustion.

3. Enough heating power

Boiler heating area is >25㎡/ton, it can absorb effective heat sufficient, low exhaust gas temperature,small heat loss,ensure enough heating power and highefficiency.

4. High steam quality

Large steam space volume and enough height of the net distance between steam water interface and steam outlet.

5. Multi-function safety explosion proof equipment

Equipped with explosion proof equipment, which can prevent fuel occur deflagration in furnace, discharge high energy. Moreover, it has the fire sight glass and inspection gallery,

it isconvenienforfurnace checking and maintaining.

6. Advanced automatic control

Boiler controller use Siemens/Delixi electrical element, reliable property. Automatic control on pressure, water temperature, and smoke temperature, etc, ensure safe operation.

7. Convenient to maintenance

There is a manhole on the top of the boiler,and some special hand hold device at middle and lower position of boiler front and back end, it’s convenient for boiler

internalinstallation, inspect and clean.

| Model | Rated evaporation capacity (t/h) | Rated steam pressure (Mpa) | Rated steam temperature (℃) | Water supply temperature (℃) | Heating area (m²) | Thermal efficiency (%) | Fuel consumption | |

| Light oil (Kg/h) | Natural gas (Nm³/h) | |||||||

| WNS1-0.7/1.0-Y(Q) | 1 | 0.7/1.0 | 170/184 | 20 | 25 | >90 | 66.5 | 75 |

| WNS1.5-1.0/1.25-Y(Q) | 1.5 | 1.0/1.25 | 184/194 | 20 | 36 | >90 | 99 | 112 |

| WNS2-1.0/1.25-Y(Q) | 2 | 1.0/1.25 | 184/194 | 20 | 60 | >90.2 | 133 | 150 |

| WNS3-1.0/1.25-Y(Q) | 3 | 1.0/1.25 | 184/194 | 20 | 77 | >90.5 | 196 | 225 |

| WNS4-1.0/1.25-Y(Q) | 4 | 1.0/1.25 | 184/194 | 20 | 113 | >91 | 266 | 300 |

| WNS5-1.0/1.25-Y(Q) | 5 | 1.0/1.25 | 184/194 | 20 | 127 | >91.3 | 332 | 375 |

| WNS6-1.25/1.6-Y(Q) | 6 | 1.25/1.6 | 194/204 | 20 | 181 | 16 | 399 | 450 |

| WN8-1.25/1.6-Y(Q) | 8 | 1.25/1.6 | 194/204 | 20 | 190 | >91.6 | 532 | 600 |

| WNS15-1.25/1.6-Y(Q) | 15 | 1.25/1.6 | 194/204 | 20 | 346 | >91.8 | 997 | 1125 |

| WNS20-1.25/1.6-Y(Q) | 20 | 1.25/1.6 | 194/204 | 20 | 467 | >92 | 1204 | 1418 |

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||||

Contact us now if you have any question about our company and products [email protected]. Any of your inquiry and suggestion will be highly appreciated. We will keep your information completely private.

WANT TO FIND A BOILER FOR YOUR COMPANY ?CONTACT US