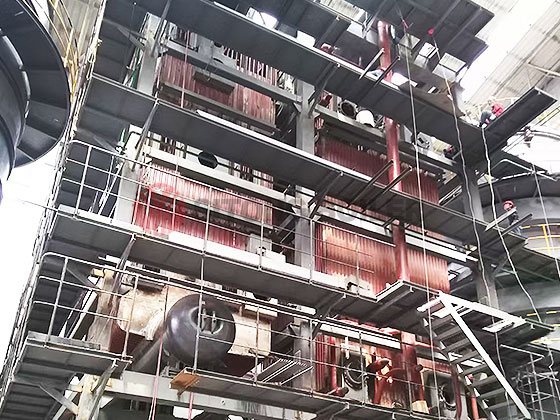

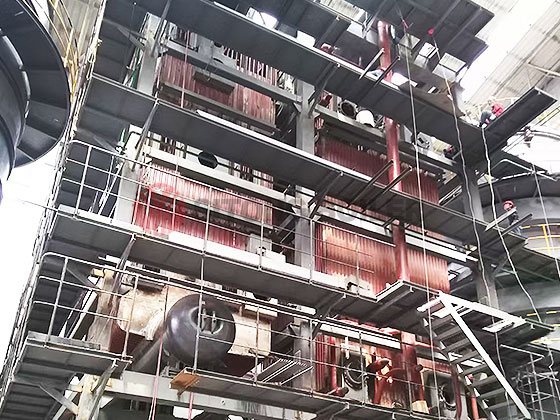

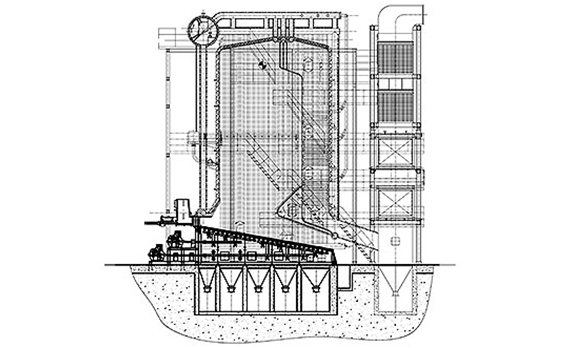

Corner tube boiler is the high-tech product with international advanced technologies, which use the technology of membrane water wall of power plant boiler to the industrial boiler, makes the boiler with better sealing performance and higher efficiency. Boiler water circulation system use the independent combination type of natural circulation and forced circulation, it has the characteristics of water circulation in safe and reliable.

edible oil, palm oil, coconut products, paper mill, rice mill, alcohol, sugar mill, textile, chemical, power plant etc.

1. High thermal efficiency

large furnace with full membrane sealing structure, more suitable for the combustion of biomass boiler. Lower heat loss, higher thermal efficiency.

2. Reduce nitrogen oxides

Secondary air design make the air distribution more uniformly and better combustion performance, it also can reduce the generation of nitrogen oxides

3. Suitable for a variety of biomass

Independent furnace arch design, suitable for many kinds of biomass.

4. Corrsgirder grate

It adopts to the corrsgirder grate, less running resisitance, better cooling performance, lower breakdown rate, less fuel leakage.

| Model | Steam Capacity(t/h) | Rated Pressure (Mpa) | Thermal Efficiency | Design Fuel |

| DHL20-1.25/1.6/2.0/2.5/3.0-AII | 20 | 1.25/1.6/2.0/2.5/3.0 | 88% | Bituminous coal, wood chips, pellet, husk, shell etc. |

| DHL25-1.25/1.6/2.0/2.5/3.0-AII | 25 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHL30-1.25/1.6/2.0/2.5/3.0-AII | 30 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHL35-1.25/1.6/2.0/2.5/3.0-AII | 35 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHL40-1.25/1.6/2.0/2.5/3.0-AII | 40 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHL50-1.25/1.6/2.0/2.5/3.0-AII | 50 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHL75-1.25/1.6/2.0/2.5/3.0-AII | 75 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| Note: Parameter is for reference only, if any changes should follow the actual drawing | ||||

Contact us now if you have any question about our company and products [email protected]. Any of your inquiry and suggestion will be highly appreciated. We will keep your information completely private.

WANT TO FIND A BOILER FOR YOUR COMPANY ?CONTACT US